what are the three basic areas of a machine that require safeguarding

The safeguard should ensure that no objects can fall into moving parts. All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls.

Pin On Best 100 Kids Childrens Face Masks 2021

That point where work is performed on the material such as cutting shaping boring or forming of stock.

. Machine safeguarding helps protect workers from preventable injuries in all three. The point of operation. Basics of Machine Safeguarding.

Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. Power transmission apparatus All components of the mechanical system which transmit energy to the part of the machine performing the work. The ins and outs of machine guarding.

Basics of Machine Safeguarding. These include moving belts arms. Dangerous moving parts in three basic areas require safeguarding.

Dangerous moving parts in three basic areas require machine safeguarding. The point where work is performed on the material such as cutting shaping boring or forming of stock. Require the operator to use both hands on machine controls this keeping both hands and body out of danger.

Automated Feeding and Ejection Mechanisms These eliminate the operators exposure to the point of operation while handling stock materials. The types of waste include processes activities products or services that require time money or skills but do not create value for the customer. The point of operation That point where work is performed.

Power Transmission all components of the mechanical system that transmit energy to the part of the machine performing the work. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area. The point of operation the power transmission device and the operating controls.

Power transmission apparatus which feeds energy to machines. Beside above what are two types of primary. All components of the mechanical system which transmit energy to the part of the machine performing the work.

What are the three primary categories of machine guarding. What are the three basic areas of a machine that require safeguarding. OSHA requires that machine hazardsmust be controlled or eliminated.

The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards that occur during normal machine operation. There are several mechanical motions that pose risks to workers. All components of the mechanical system which transmit energy to the part of the machine performing the work.

There seem to be as many hazards created by moving machine parts as there are types of machines. The safeguard must prevent hands arms and any other part of a workers body from making contact with dangerous moving parts. What are the three basic areas of a machine that require safeguarding.

Safeguards must meet these minimum general requirements. Safeguards are essential for protecting workers from needless and preventable. The point of operation from where all the work is performed.

The point of operation. These components include flywheels. The point where work is performed on the material such as cutting shaping boring or forming of stock.

Specially constructed safeguards ventilation and protective equipment and clothing are possible temporary solutions to the problem of machinery-related chemical hazards until these hazards can be better controlled or eliminated from the workplace. Dangerous moving parts in three basic areas require safeguarding. Safeguards may be categorized under five general classifications.

These components include flywheels. Protect from falling objects. That point where work is performed on the material such as cutting shaping boring or forming of stock.

The machine designer or safety professional must choose the most effective and practical safeguard available. Rotating reciprocating and transverse. Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

The point of operation. Dangerous moving parts in three basic areas require safeguarding. Point of Operation that point where work is performed on the material such as cutting shaping boring or forming of stock.

Devices these limit or prevent access to the hazardous area. Moving parts which are part of the machine or bigger system. A safety device may perform one of several functions.

Dangerous moving parts in three basic areas require safeguarding. Moving machine parts create workplace hazards and potential machinery-related injuries making machine guards vitally important. OSHA states that mechanical hazards are most likely to occur in three major areas.

All components of the mechanical system which transmit energy to the part of the machine. The point of operation. All components of the mechanical system which transmit energy to the part of the machine performing the work.

Guards these are physical barriers that prevent contact. The point of operation. Machine Guarding Introduction All machines consist of three fundamental areas.

Restrain or withdraw the operators hands from the danger area during operation. Cutting Shaping Boring Forming 2. Three basic area require machine safeguarding.

Dangerous moving parts in threebasic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding. The point of operation is the area on a machine where the work is performed.

1 guards 2 devices 3 separation 4 operations and 5 other. Or provide a barrier which is. There are three permissible exceptions to the basic rule on patentability.

All components of the mechanical system which transmit energy to the part of the machine performing the work. Point of Operation Power Transmission Apparatus Other Moving Parts Question 2.

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Iso 14120 2015 En Safety Of Machinery Guards General Requirements For The Design And Construction Of Fixed And Movable Guards

Three Steps To Preventing Machine Injuries Ul

Chapter 1 Basics Of Machine Safeguarding

Machine Guards For Industrial Robots Satech Machine Guards

Three Steps To Preventing Machine Injuries Ul

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Cloudflare Completes Acquisition Of Area 1 Security In 2022 Security Network Security Areas

Abb Launched Irb 6790 Foundry Prime Robot Which Is Used At High Pressure Water Jet Cl Life Cycle Management Information And Communications Technology Marketing

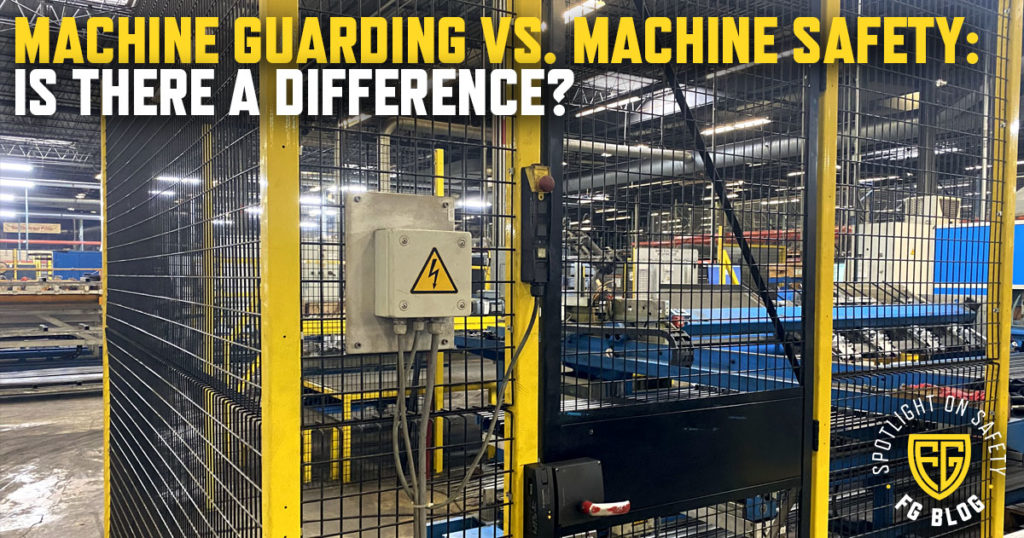

Machine Safety And Machine Guarding Are They The Same Or Different

Essential Updates To Machine Safety Standards Ul

Hambrick And Fredrickson S Strategy Diamond Fourweekmba Strategies Core Beliefs Fifth Element

Chapter 1 Basics Of Machine Safeguarding

Data Science Vs Data Analytics On Different Basis Data Science Data Analytics Data Visualization

Chapter 1 Basics Of Machine Safeguarding

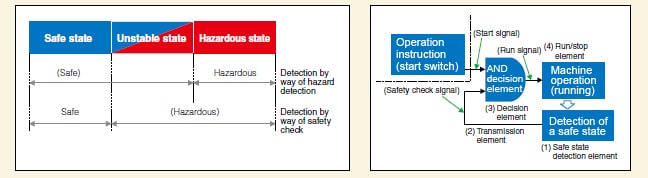

3 Step Method Safety Knowledge Keyence International Belgium

![]()

The Three States Of Data Guide Description And How To Secure Them

Michael Fisher On Twitter Technology And Society Marketing Technology Marketing

Celebrating Three Years Of Liquid Metal In Rog Laptops Rog Republic Of Gamers Global